Why Scrubber Washwater Monitoring Matters

Ensure Compliance with VGP & EGCS Discharge Requirements

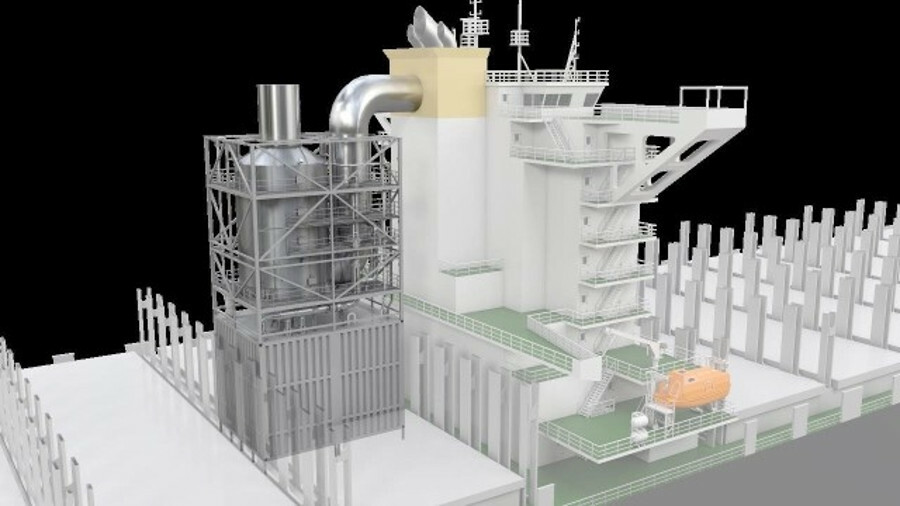

When a vessel uses an exhaust gas cleaning system (scrubber/EGCS), the washwater discharged must be monitored to ensure it complies with regulatory requirements. Under the Vessel General Permit (VGP) in U.S. waters, washwater from exhaust-gas scrubbers is subject to analytical monitoring.

Further, international guidelines such as MARPOL Annex VI and IMO EGCS Guidelines (MEPC.259(68) / MEPC.340(77)) point to required parameters including pH, metals, PAHs, nitrates/nitrites and more. Διεθνές Συμβούλιο Καθαρών Μεταφορών+1

Failing to monitor or retain onboard records can expose vessel owners/operators to non-compliance, detention risk, and reputational issues.

Regulatory Requirements at a Glance

In the first year of permit coverage or system operation (whichever comes first), vessel owner/operators must collect two separate samples (not within 14 days of each other) for each relevant constituent.

Sampling must cover three locations:

- Inlet water (background)

- Water after the scrubber (but before any treatment)

- Discharge water

After the first year, sampling must be done at least once per calendar year at the three locations.

Records of sampling and testing results must be retained onboard the vessel for at least three years, in line with permit record-keeping requirements.

For pH limits: Under VGP the washwater discharge must have a pH of no less than 6.0 measured at the overboard discharge. Some international guidelines require a minimum pH of 6.5.

Exhaust Gas Scrubber Washwater

Below are the key groups of analytes your vessel should be testing for as part of the scrubber washwater monitoring regime:

Dissolved & Total Metals

Arsenic, Cadmium, Chromium, Copper, Lead, Nickel, Selenium, Thallium, Vanadium, Zinc

Polycyclic Aromatic Hydrocarbons (PAHs)

Acenaphthylene, Acenaphthene, Anthracene, Benz[a]anthracene, Benzo[ghi] perylene, Benzo[a]pyrene, Benzo[b]fluoranthene, Benzo[k] fluoranthene, Chrysene, Dibenz[a,h]anthracene, Fluoranthene, Fluorene, Indeno[1,2,3-cd]pyrene, Naphthalene, Phenanthrene, Pyrene

Other Parameters

- Nitrite/Nitrate

- pH

- (Additional parameters may also be required depending on region/flag/state)

Our Service Offering

We provide a turnkey solution for scrubber washwater analysis that takes the burden off your ship-operations and ensures compliance. Our service includes:

- Sampling kits pre-packed with all required materials (sampling bottles, preservatives, labels) ready for vessel use.

- Logistics & transportation of kits to your vessel and subsequent shipment of samples to the laboratory within required timeframes.

- Clear step-by-step sampling instructions tailored for onboard crew/engineers to ensure correct procedure and chain of custody.

- Laboratory analysis performed using EPA or internationally approved methods consistent with the VGP and IMO requirements.

- Comprehensive report including analytical results, benchmark comparison, commentary on compliance, and graphical summaries.

- Guidance on record-keeping and documentation to assist with Port State Control (PSC) inspections and flag-state audits.

Why Choose Us?

- Deep experience supporting scrubber washwater compliance globally.

- Fast turnaround from sampling to report.

- Recognised by ship-operators, Class-societies and PSC regimes.

- Flexible service: from full boards to kit-only depending on your needs and vessel schedule.

- Transparent pricing and clear deliverables — no “hidden extras”.

Next Steps – Get Compliant Today

Contact our team to discuss your vessel details (flag, scrubber type, operating area) so we can tailor a sampling plan that meets your needs and regulatory obligations.

- Ready to order a sampling kit and schedule an onboard sampling service?

- Need an annual compliance package including logistics, lab analysis and reporting for your fleet?

Contact our team to discuss .We are here to make your scrubber washwater monitoring reliable, documented and compliant.